by Ed Juline, CPMR, CSP, Mexico Representation

What are the odds that your very first deal as a manufacturers’ representative turns out to be a long-term contract on $50 million in sales per year and you’re guaranteed to land the project with one of the handful of manufacturers you are working with?

The intention for this column is to provide new and old reps with horror stories from the field so that we can use our collective experience to help each other avoid some of the common and not-so-common pitfalls of our profession.

You know the type of phone call — totally out of left field from someone you haven’t heard from in a few years, “I know a guy who knows a guy who needs to move his manufacturing to a new supplier.” In this case, it was an original equipment manufacturer (OEM) with their own manufacturing facility in the Midwest that needed to outsource. For security reasons, they couldn’t move the manufacturing to China. Mexico was the logical solution, and so I was contacted to find a plastic injection molder who could do somewhat high-tech secondary assembly operations on over $50 million in production per year. I lined up three potential suppliers but also got a lead on a fourth that would have to go through another rep. Signing rep contracts with the first three was pretty straightforward, but the fourth one would have to be a sub-rep agreement where I would only get 40 percent on his 5 percent commission contract with the contract manufacturer (CM).

The OEM flew down to Mexico and visited all four, with the fourth option being their favorite. The contract between the OEM and the CM was signed, the tools and machinery moved to their facility and the primary rep and I were having long conversations about where we were going to spend all the commissions.

The first commission check came in at about $2,500, and we assumed it was just due to ramp-up. When the second month came in at $1,300 and the third at $1,800, we demanded a written accounting for the commissions. We discovered that the commission rate on their reports was <0.01 percent and demanded an explanation. We were told that the commission rate on the report would be the commission rate they were going to pay and with the primary rep being a semi-full-time litigation participant, we demanded arbitration.

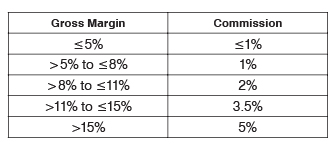

We started the arbitration session with a review of the contract and it was immediately pointed out that the commissions were to be determined by a commission schedule. It was in this moment that I realized I had never seen a copy of the contract between the primary rep and the CM. Sure enough, in black and white was Exhibit A — Commission Schedule with the following table:

Before confronting my “partner” on why he had told me from the start that he had a 5 percent commission contract when it was something much different, I decided that we needed to understand how a completely transparent transfer project quoted with a 12 percent margin could result in less than 5 percent gross margin. The CM presented us with their financial statements which showed that the project was not only not at 5 percent gross margin but actually below 1 percent gross margin and thus they were giving us a discretionary commission of 0.01 percent, complying with the ≤1 percent commission in the commission schedule. A deeper dive into the CM financials showed that all of the non-project overhead the CM had (cafeteria, cleaning, insurance, etc.) was being assigned to this project and thus the 12 percent margin turns into <1 percent for the set of books you use to justify your commission payments.

The point at which I realized I was not going to be able to retire at 34 years old was when the primary rep told the arbitrator, “Well…I didn’t mean to sign that contract.”

A month later, the primary rep and the CM agreed on a $200k settlement to terminate the rep contract. After legal fees, I received a check for $60k and my big fat first venture into being a manufacturers’ rep ends up as an anecdote in the pages of Agency Salesmagazine.

Lessons Learned

- When signing a sub-rep contract, insist on seeing the primary rep’s contract.

- Always try to control the contractual situation yourself and only enter a sub-rep agreement when you know you can trust the other party.

- When a partner, associate, customer or supplier brags about how many lawsuits they’ve won (or lost) over the years, run.

- Don’t leave arbitrary, conditional and open-ended commission rates in contracts.

- Share your contracts with other reps to see if they see anything you might not see.

Ed Juline, CPMR, CSP, has been working in manufacturing operations and sales in Mexico for 15 years. When IBM decided to move the manufacturing from North Carolina to Guadalajara, Jalisco, they needed someone to lead the project. Juline raised his hand and said “I’ll do it!” After a successful transplant, he wasn’t quite done with Mexico, taking the severance that a non-manufacturing IBM was offering and going on to work for Nypro as the Dell Business Unit manager and then Pertek-Erler as plant manager. When MacDermid Autotype wanted to get into the Mexican market and searched LinkedIn for the keywords “Mexico Plastics Appliances,” Juline’s profile was at the top of the list. The transition to sales led to solicitations for representation from a number of companies wanting to sell into Mexico and Mexico Representation was formed.